Environment

We see the dangers of climate change and its consequences. We intend to gradually reduce our carbon footprint and continue to take a responsible approach to environmental protection.

Our steel production has undergone significant changes thanks to investments in the latest technologies and is one of the most environmentally friendly in Europe. All production facilities meet BAT requirements, without any exceptions, and we meet strict environmental limits in protecting air, water and soil every year. We strive for maximum recycling and recovery of by-products and waste generated in our production processes.

As a 100% recyclable material, steel ideally fulfils the principles of the circular economy, which is an important part of the effort to save the planet.“

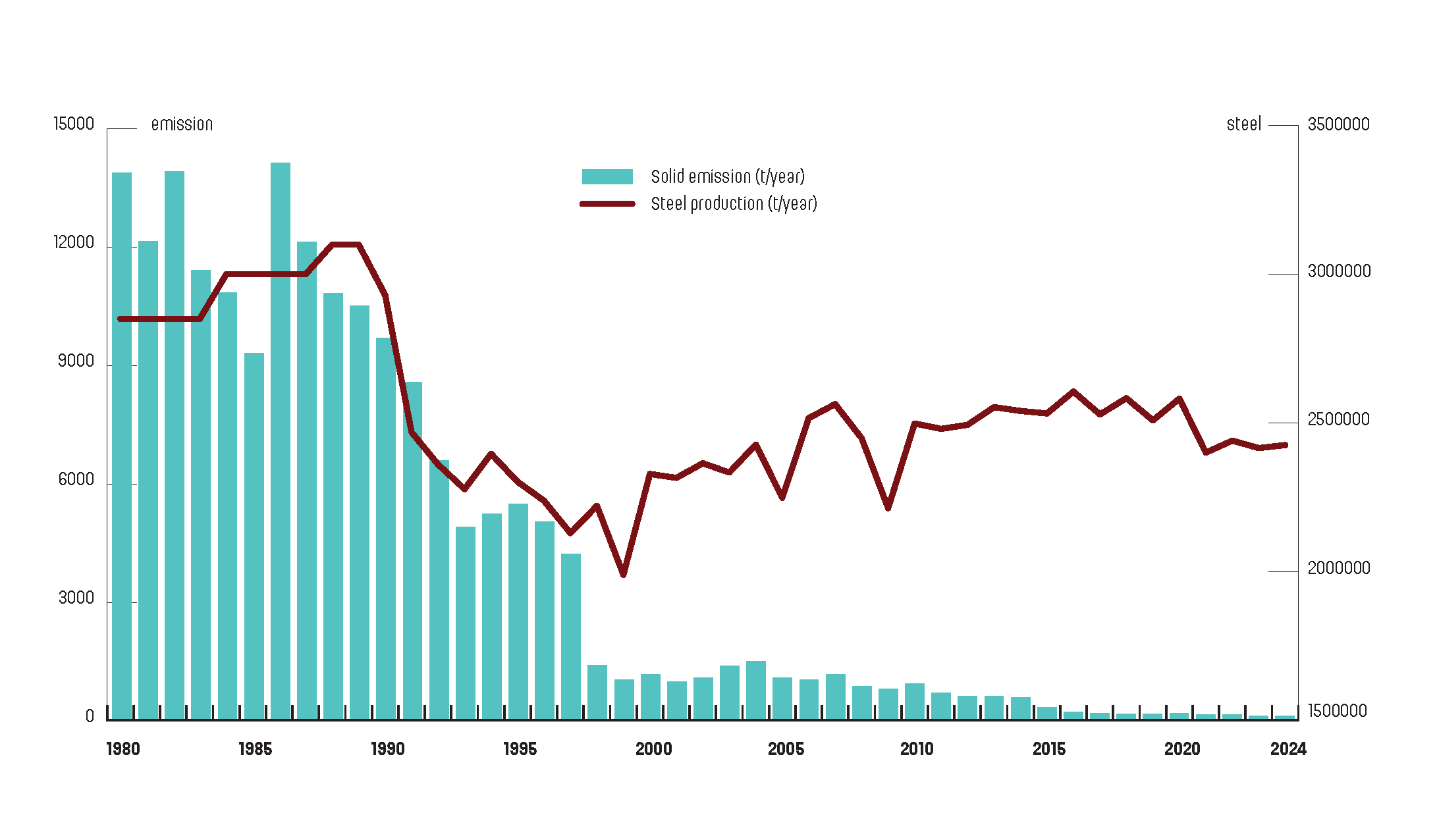

Třinecké železárny pays great attention to the impact on climate change and the reduction of greenhouse gas emissions. Thanks to a number of completed ecological projects, we have succeeded in significantly reducing dust emissions as well as emissions of polycyclic aromatic hydrocarbons and dioxins. We are taking an active approach to reducing greenhouse gases through massive tree planting. The aim of all our activities and investments is to gradually reduce emissions by 55% by 2030 compared to 1990.

In the field of water protection, we strive to make economic use of this natural resource. Closed water circuits have been built at all production sites of the smelter to ensure recirculation of industrial water. All industrial wastewater is monitored and transferred to other entities for treatment in accordance with the relevant sewage regulations.

Třinecké železárny generates a wide range of waste, including hazardous waste. Waste is handled in full compliance with applicable legislation. First and foremost, our aim is to prevent the generation of waste and, if this is not possible from a technical or economic point of view, to ensure that the waste generated is used for material or energy recovery.

The circular economy is an important part of our efforts to save the planet.

Setting annual energy saving and efficiency targets has a positive impact on reducing greenhouse gas emissions. Other measures include the annual planting of new greenery, maintenance of large existing green spaces, and renewable energy projects. A challenging project to transform steel production technology is also under preparation with the aim of significantly reducing CO2 emissions by 2030.

An important part of the environmental protection programme is also the care of the greenery in the area of the company, respect for the bio-corridor of the Olše River and its tributaries, and the protection and promotion of wildlife.